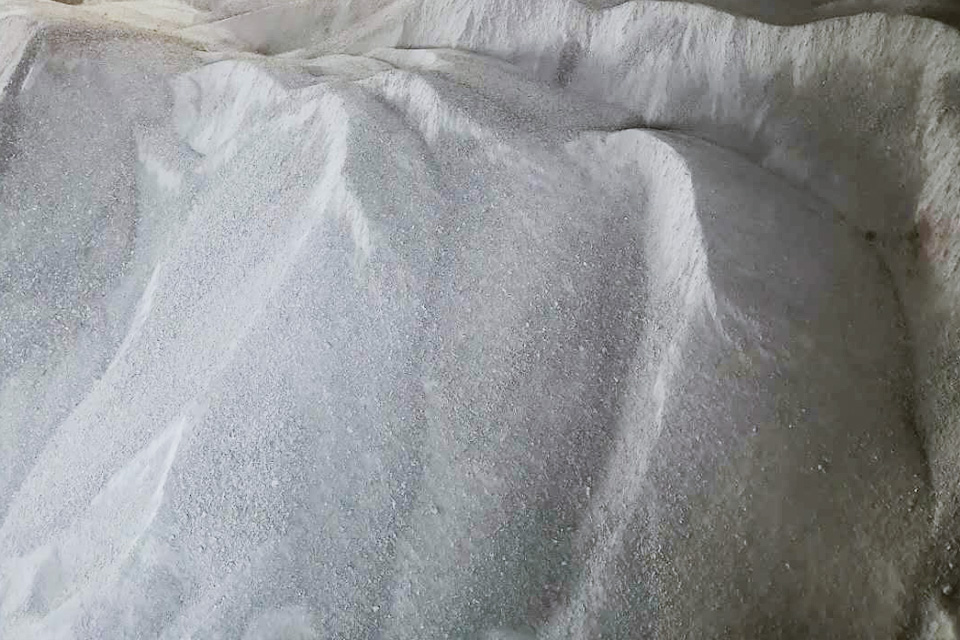

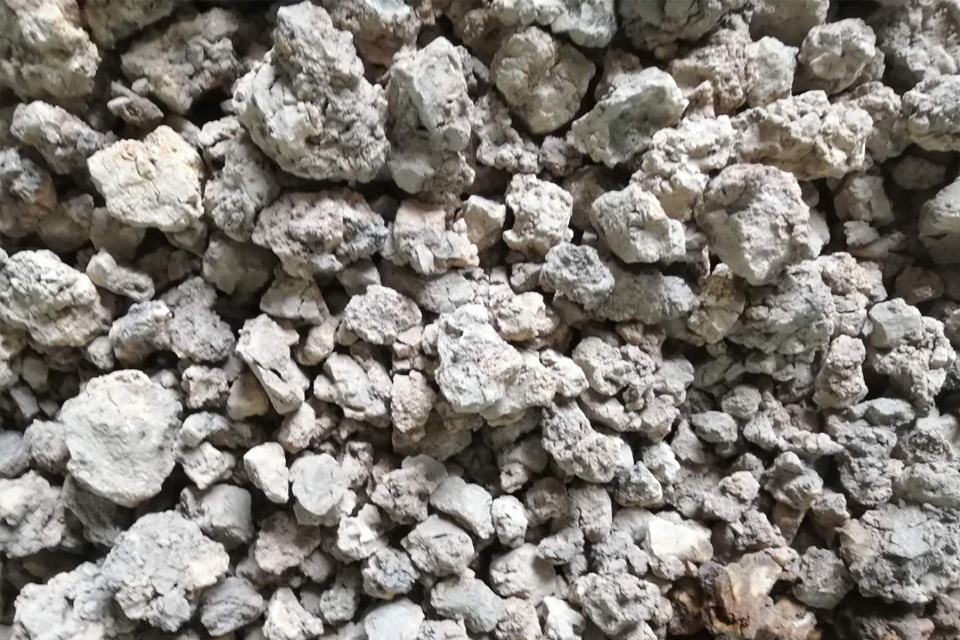

High iron sand

Due to the uneven mixing of magnesia and iron powder, the sintering performance and use effect are not good. The magnesia powder and iron phosphorus are calcined together in proportion and then used in the filling furnace, which significantly improves the service performance. The high iron sand produced by our factory, HMF68A, increases the CaO content, and it mainly exists in the type of 2CaO. Fe2O3 in C2F is solid melted into magnesite at high temperature, which improves the intergranular C/S of magnesite. It is easy to sinter and easy to use. It is a good raw material for filling lining and filling bottom of modern electric furnace and LD converter.

PRODUCT DETAILS

Grade | Refers to the standard | |||||

MgO%≥ | SiO2%≤ | Fe2O3%≤ | CaO% | Al2O3 %≤ | Grain sire%≤ | |

HMF68A | 65-72 | 2.5 | 10 | 5 | 1.2 | 0.3 |

HMF68B | 65-72 | 3.0 | 10 |

| 1.5 | 0.3 |